The Rise of Smart Tea Factories

“When Engineering Meets Intelligence”

For over a century, tea factories have thrived on craftsmanship, the intuition of a factory superintendent, the rhythm of a rolling room, and the fine balance between leaf and time. But as energy costs rise and global buyers demand consistent quality and traceability, the next great transformation in the tea industry is already underway. The Smart Tea Factory is not a futuristic idea anymore; it is today’s quiet revolution.

Across Sri Lanka, Kenya, and India, a new generation of producers is integrating digital intelligence and engineering precision to transform traditional tea-making into a data-driven art. The goal is simple yet profound — maintain the heritage of craftsmanship while ensuring every process is measurable, repeatable, and efficient.

From Manual Mastery to Digital Precision

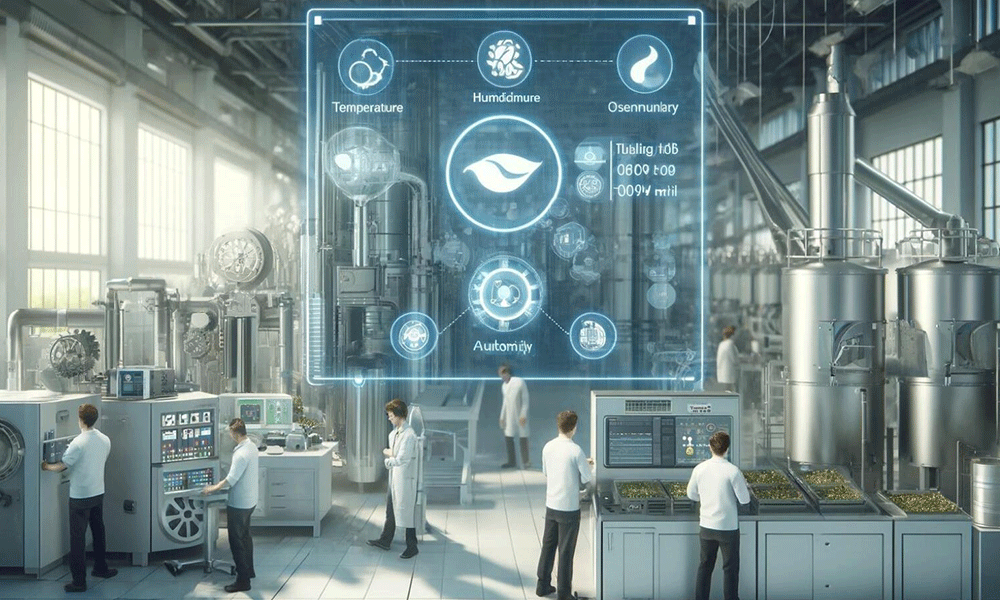

In a conventional factory, withering, rolling, and fermentation depend on experience. But experience alone can’t always ensure consistency under fluctuating humidity, leaf moisture, and temperature. That’s where smart sensors and Internet of Things (IoT) technology come in.

By embedding sensors across withering troughs, rollers, dryers, and fermentation rooms, factory managers can now monitor environmental conditions in real time. Data streams from these sensors feed into centralized dashboards, alerting teams instantly when temperatures rise too high or rolling pressures exceed optimum levels. What once required human intuition is now supported by continuous feedback, allowing operators to act before quality drifts.

In trials across leading South Asian factories, IoT-based monitoring has cut variability in moisture retention by up to 15%, and reduced unplanned stoppages by nearly 30%. The combination of Walkers’ engineering reliability with real-time data offers a new kind of efficiency — one rooted in precision, not just productivity.

Automation: The Gentle Partner of Craft

Automation in tea doesn’t replace the art of tea-making — it amplifies it. Automated pressure control in rolling machines ensures every batch receives uniform treatment, protecting the leaf structure and reducing reprocessing losses. Intelligent fermentation systems, guided by humidity and temperature sensors, allow for exact oxidation, giving every leaf its distinctive brightness and body.

More advanced systems integrate machine learning, learning from previous batches to refine process parameters. In essence, the machine becomes a quiet apprentice — learning from the master’s judgment and repeating perfection at scale.

The Business Case for Smart Factories

While technology investment may appear capital-intensive, the long-term gains are measurable. Early adopters in Kenya and Sri Lanka report:

- Energy savings of 10–20% through smarter motor controls and optimized airflow.

- Reduced manpower dependence in repetitive monitoring tasks.

- Predictive maintenance, extending machine life and minimizing downtime.

- Data-backed traceability, meeting European and Japanese buyer requirements.

In financial terms, a mid-sized factory can often recover its initial digital investment within 24–30 months, largely through reduced waste and energy savings alone.

Engineering Meets Analytics

Walkers’ next-generation machinery is already designed with digital integration in mind, equipped for sensor retrofits, motor control upgrades, and data linkages. The company’s R&D team is exploring unified control interfaces, allowing operators to monitor all major processes — from withering to sorting — through a single platform.

For executives, this means greater control, better reporting, and stronger compliance. For engineers, it brings the joy of seeing data confirm what their experience has always known. And for tea buyers, it ensures that the leaf they purchase carries a signature of consistency and authenticity.

A Smarter Future, Rooted in Heritage

The tea industry’s digital shift is not about abandoning its soul. It’s about strengthening it. Smart tea factories preserve what matters most — the delicate chemistry between leaf, air, and time — while using intelligence to ensure those conditions remain perfect in every cycle.

When engineering meets intelligence, quality becomes predictable, energy becomes accountable, and heritage becomes scalable. In a world demanding both excellence and efficiency, the smart factory is not the future — it is the new definition of tradition itself.